Introduction to Robotics and Automation in Manufacturing

Imagine a factory floor buzzing with precision, where machines work tirelessly alongside humans, handling tasks with speed and accuracy that seem almost superhuman. This is the reality of modern manufacturing, transformed by robotics and automation. These technologies have become the backbone of industries worldwide, driving efficiency, safety, and innovation. From automotive giants to small-scale electronics producers, robotics is reshaping how goods are made, and I’m here to walk you through this fascinating evolution.

The Evolution of Robotics in Manufacturing

The Dawn of Industrial Robots

Back in the 1960s, a hulking machine named Unimate changed the game at a General Motors plant. It was the first industrial robot, tasked with moving scalding-hot car parts—a job too dangerous and repetitive for humans. This marked the birth of robotics in manufacturing, a moment that sparked a revolution still unfolding today. Unimate’s success showed the world that robots could handle the “dull, dirty, and dangerous” tasks, freeing workers for more complex roles.

From Fixed Machines to Smart Systems

Fast forward to the 21st century, and robotics has leaped from clunky, pre-programmed arms to intelligent systems powered by artificial intelligence (AI) and machine learning. These modern robots don’t just follow scripts—they adapt, learn, and make decisions. I remember visiting a factory where a robot adjusted its welding path in real-time based on slight variations in car parts. It was like watching a craftsman, but with the precision of a machine. This shift to “smart” robotics is the heart of Industry 4.0, where factories are becoming interconnected hubs of innovation.

Key Types of Robots in Manufacturing

Industrial Robots

Industrial robots, like articulated arms or SCARA (Selective Compliance Assembly Robot Arm) robots, are the workhorses of manufacturing. They excel at tasks requiring precision, such as welding car bodies or assembling circuit boards. These robots are often stationary, designed for high-volume, repetitive tasks, and can operate 24/7 without a coffee break—unlike me, who needs one just writing this

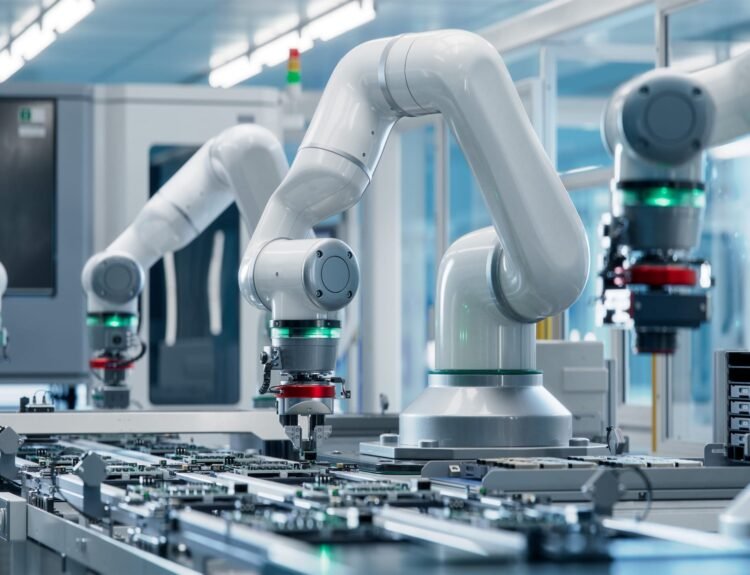

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are the friendly cousins of industrial robots. Designed to work alongside humans, they’re equipped with sensors to avoid collisions and ensure safety. Picture a cobot handing tools to a worker or assembling delicate electronics with a human’s oversight. Their flexibility makes them a favorite in smaller factories where adaptability is key.

Autonomous Mobile Robots (AMRs)

AMRs are the free spirits of the robot world, navigating factory floors without fixed paths. Using cameras and lasers, they transport materials or products, dodging obstacles like a seasoned delivery driver. I once saw an AMR zip through a warehouse, delivering parts to different stations—it was like watching a sci-fi movie, but it was just another day at work.

Table: Comparison of Robot Types in Manufacturing

| Robot Type | Key Features | Primary Applications | Best For |

|---|---|---|---|

| Industrial Robots | High precision, stationary, programmable | Welding, assembly, material handling | High-volume, repetitive tasks |

| Collaborative Robots | Safe for human interaction, flexible | Assembly, packaging, inspection | Small to medium-scale operations |

| Autonomous Mobile Robots | Mobile, autonomous navigation | Material transport, logistics | Dynamic, flexible environments |

Applications of Robotics and Automation in Manufacturing

Material Handling and Logistics

Robots are the unsung heroes of material handling, moving raw materials or finished goods with speed and precision. Pick-and-place robots, for instance, grab parts from one conveyor and place them on another, streamlining workflows. AMRs take it a step further, transporting goods across factories, reducing manual labor and the risk of injury.

Assembly and Production

From screwing bolts to assembling intricate electronics, robots dominate assembly lines. In automotive plants, robots handle tasks like installing door panels or seats, which would otherwise cause repetitive strain injuries to workers. Their precision ensures every product meets exact specifications, boosting quality and consistency.

Welding and Painting

Robotic welding, especially in the automotive industry, is a game-changer. Robots perform spot and arc welding with unmatched accuracy, reducing defects and worker exposure to hazardous fumes. Similarly, robotic painting ensures even coats on everything from cars to consumer goods, cutting down on waste and rework.

Quality Inspection

Robots equipped with vision systems and sensors are like eagle-eyed inspectors. They scan products for defects, measure dimensions, or read barcodes, ensuring only top-quality items leave the factory. This level of scrutiny is critical in industries like pharmaceuticals, where precision is non-negotiable.

Packaging and Palletizing

Packing and palletizing robots streamline the final stages of production. They place products into containers or stack them on pallets with speed and accuracy, preparing them for shipment. This automation not only saves time but also reduces errors, ensuring products reach customers in perfect condition.

Benefits of Robotics and Automation in Manufacturing

Enhanced Productivity and Efficiency

Robots don’t take breaks or get distracted by the latest viral video. They work around the clock, boosting output by 20–25% in some cases, as seen in Spanish manufacturing firms. This efficiency allows companies to meet tight deadlines and scale production without hiring armies of workers.

Improved Quality and Precision

Human hands are skilled, but robots are relentless in their precision. Whether it’s welding a car frame or assembling a microchip, robots reduce errors and ensure consistent quality. This is why industries like aerospace rely on them for critical components where even a millimeter’s error could be catastrophic.

Increased Safety

Robots take on the “three Ds”—dull, dirty, and dangerous tasks. By handling heavy lifting or working in hazardous environments, they reduce workplace injuries. I recall a factory worker telling me how a cobot saved him from lifting heavy wheels, sparing his back and letting him focus on skilled tasks.

Cost Savings

While the upfront cost of robots can be steep, the long-term savings are undeniable. Robots reduce labor costs, minimize waste, and lower error rates, leading to significant ROI. For small manufacturers, cobots offer an affordable entry point, making automation accessible to all.

Pros and Cons of Robotics in Manufacturing

Pros:

- Boosts productivity and output

- Enhances product quality and consistency

- Reduces workplace injuries

- Lowers long-term operational costs

- Enables flexibility in production

Cons:

- High initial investment

- Requires skilled workers for programming and maintenance

- Potential job displacement for low-skilled workers

- Integration challenges with existing systems

Challenges and Limitations

High Initial Costs

Buying and installing robots isn’t cheap. For small manufacturers, the cost of a single industrial robot can feel like buying a sports car. While cobots are more affordable, the overall investment, including training and integration, can strain budgets.

Workforce Displacement Concerns

The fear of robots “stealing” jobs is real. Studies show that adding one robot per thousand workers can reduce employment by six workers in certain areas. However, this displacement often shifts workers to higher-skilled roles, like programming or maintenance, which can be a silver lining if training is provided.

Psychological Barriers and Technophobia

Not everyone’s thrilled about working with robots. Some workers worry about safety or feel uneasy about machines taking over tasks. Building trust through training and demonstrating safety features, like cobots’ sensors, is crucial to easing these concerns.

Technical and Integration Issues

Integrating robots into existing workflows can be like teaching an old dog new tricks. Factories often face challenges aligning robots with legacy systems or ensuring seamless communication in smart factories. This requires careful planning and expertise.

The Role of Industry 4.0 and Beyond

Smart Factories and IoT Integration

Industry 4.0 has turned factories into interconnected ecosystems. Robots, linked via the Internet of Things (IoT), communicate with machines and systems in real-time, optimizing production. For example, a robot might detect a supply chain hiccup and adjust its tasks, ensuring minimal downtime.

AI and Machine Learning in Robotics

AI is the brain behind modern robots. Machine learning allows them to analyze data, predict maintenance needs, or adapt to new tasks without explicit programming. This intelligence is transforming robots from mere tools to active decision-makers in manufacturing.

The Rise of Industry 5.0

Industry 5.0 takes automation a step further by emphasizing human-robot collaboration. It’s about combining human creativity with robotic precision. Imagine a factory where workers and cobots brainstorm solutions together—well, maybe not brainstorm, but you get the idea. This human-centric approach is shaping the future of manufacturing.

Real-World Examples of Robotics in Action

Automotive Industry: Tesla’s Gigafactory

Tesla’s Gigafactory is a robotics marvel, with hundreds of robots welding, assembling, and painting electric vehicle components. These robots work in sync, reducing production time and ensuring every car meets Tesla’s high standards. It’s a glimpse into the future of automotive manufacturing.

Electronics: Foxconn’s Automation Push

Foxconn, a major electronics manufacturer, uses robots for tasks like assembling iPhones. Their precision ensures tiny components are placed perfectly, while AMRs shuttle parts across massive factories. This automation has helped Foxconn stay competitive in a fast-paced industry.

Small-Scale Success: Odico’s Drill Mate

Danish wind turbine manufacturer Odico developed the Drill Mate robot to drill precise patterns into massive blades. This robot adapts to design changes, proving that even niche applications can benefit from robotics. It’s a reminder that automation isn’t just for giants.

People Also Ask (PAA) Section

What are the main types of robots used in manufacturing?

The main types include industrial robots (like articulated arms), collaborative robots (cobots) that work with humans, and autonomous mobile robots (AMRs) for material transport. Each type is suited for specific tasks, from welding to logistics, enhancing efficiency and safety.

How do robots improve manufacturing efficiency?

Robots boost efficiency by performing repetitive tasks faster and with greater precision than humans. They reduce errors, minimize downtime, and operate continuously, leading to higher output and cost savings, especially in high-volume production.

What are the challenges of implementing robotics in manufacturing?

Challenges include high initial costs, workforce displacement, integration issues with existing systems, and psychological barriers like technophobia. Overcoming these requires investment in training, safety measures, and strategic planning.

Where can I find robotics solutions for my factory?

Companies like Universal Robots, FANUC, and ABB offer robotics solutions tailored to manufacturing needs. Check their websites or contact local distributors for customized recommendations. Trade shows like Automate also showcase the latest technologies.

Best Tools and Providers for Robotics in Manufacturing

Top Robotics Companies

- Universal Robots: Known for user-friendly cobots ideal for small to medium-sized manufacturers. Visit Universal Robots

- FANUC: Offers a wide range of industrial robots for high-volume tasks like welding and assembly. Visit FANUC

- ABB: Specializes in advanced robotics and IoT integration for smart factories. Visit ABB

Software and Integration Tools

- Rockwell Automation’s Plex Platform: A smart manufacturing platform for integrating robotics with factory systems. Visit Plex

- RoboDK: A simulation software for programming and optimizing robotic workflows. Visit RoboDK

- ROS (Robot Operating System): An open-source framework for developing robot applications. Visit ROS

Comparison: Industrial Robots vs. Cobots

| Feature | Industrial Robots | Cobots |

|---|---|---|

| Cost | High ($50,000–$200,000) | Moderate ($20,000–$50,000) |

| Safety | Requires fencing | Built-in safety sensors |

| Flexibility | Fixed tasks | Adaptable to multiple tasks |

| Best Use Case | High-volume production | Small-batch, human-assisted |

FAQ Section

How do robots impact jobs in manufacturing?

Robots can displace low-skilled jobs but also create high-skilled roles in programming, maintenance, and data analysis. Upskilling programs are key to helping workers transition.

Are robots safe to work with in factories?

Yes, especially cobots, which are designed with sensors to stop if they detect humans. Safety protocols and training further ensure a secure workplace.

What’s the ROI for investing in manufacturing robots?

ROI varies but can be significant due to reduced labor costs, fewer errors, and higher output. Small manufacturers often see returns within 1–2 years with cobots.

How do I choose the right robot for my factory?

Assess your needs (e.g., task type, volume, budget) and consult with providers like FANUC or Universal Robots. Pilot programs can help test solutions before full investment.

Can small businesses afford robotics?

Yes, cobots and entry-level automation solutions are designed for small businesses, with lower costs and easier integration than traditional industrial robots.

The Future of Robotics in Manufacturing

Emerging Trends

The future is bright—and robotic. Soft robotics, using flexible materials, is gaining traction for handling delicate items like food or medical supplies. AI advancements will make robots even smarter, enabling predictive maintenance and autonomous decision-making. Plus, the rise of Industry 5.0 will prioritize human-robot synergy, creating workplaces where creativity and automation coexist.

Preparing for the Future

Manufacturers must invest in training to prepare workers for a robotic future. Upskilling in programming, AI, and robotics maintenance will be crucial. Partnerships with tech providers and research institutions can also keep companies ahead of the curve. I’ve seen factories thrive by embracing this mindset, turning challenges into opportunities.

Conclusion: Embracing the Robotic Revolution

Robotics and automation are no longer futuristic dreams—they’re the present and future of manufacturing. From boosting productivity to enhancing safety, these technologies are transforming how we make everything from cars to smartphones. Yes, challenges like costs and workforce transitions exist, but the benefits far outweigh them. As someone who’s seen robots turn chaotic factories into models of efficiency, I can say this: embracing robotics isn’t just smart—it’s essential. Ready to automate your factory? Start small, think big, and watch your production soar.