Introduction to Robotics and Automation

Picture this: a factory humming with activity, where machines zip along assembly lines, churning out products with precision. Nearby, a robotic arm delicately places components together, almost like a chef crafting a perfect dish. Are these machines part of robotics or automation? The terms are often tossed around interchangeably, but they’re not the same. Understanding the difference between robotics and automation is crucial for anyone diving into modern technology, whether you’re a business owner, a tech enthusiast, or just curious about the future. This article unpacks the distinctions, their applications, and why it matters to you.

What is Robotics?

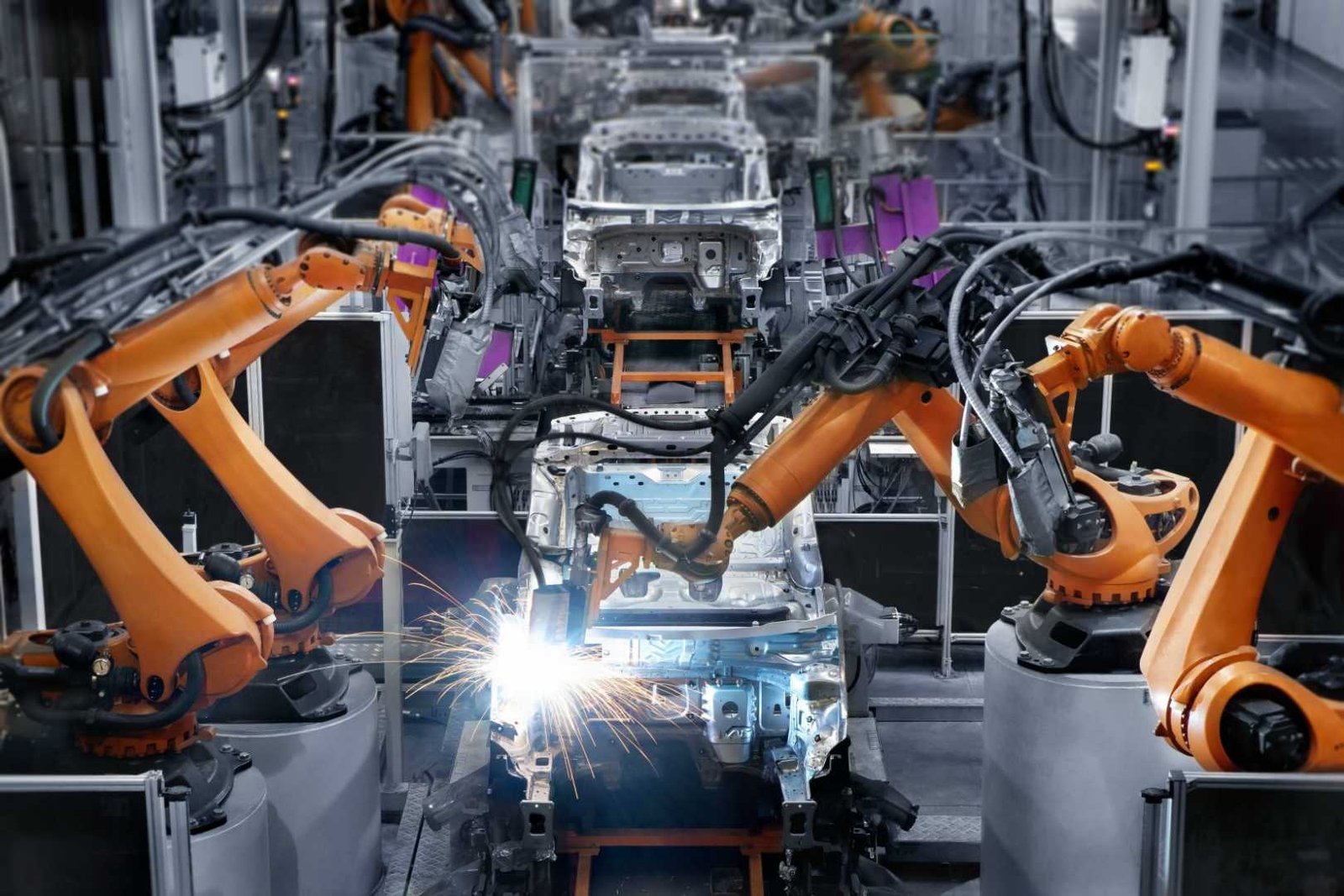

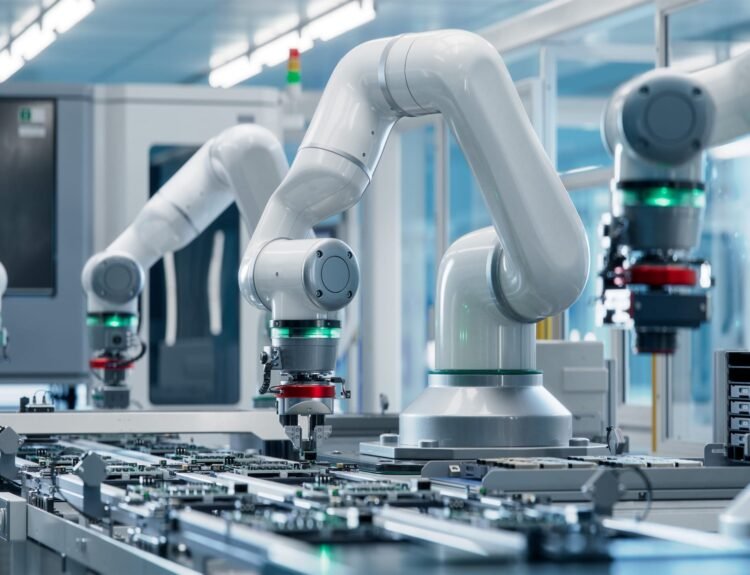

Robotics is the science of designing, building, and operating robots—physical machines that can perform tasks with a degree of autonomy. Think of a robotic arm welding car parts or a humanoid robot assisting in a hospital. Robotics combines engineering, computer science, and artificial intelligence to create machines that mimic human actions or perform tasks humans can’t.

Why Robotics Feels Like Sci-Fi

Robotics captures our imagination because it feels like something out of a movie. I remember watching a robot dog navigate a parkour course at a tech expo, dodging obstacles with eerie precision. It wasn’t just programmed; it learned its environment. That’s robotics: machines with brains, bodies, and a knack for problem-solving.

What is Automation?

Automation is about streamlining processes by using technology to perform tasks with minimal human intervention. It’s the software that schedules your emails, the conveyor belt that moves packages, or the thermostat that adjusts your home’s temperature. Automation doesn’t always involve physical machines—it can be purely digital, like a script that organizes your spreadsheets.

Automation in Everyday Life

Automation is so woven into our lives that we barely notice it. Last week, I set my coffee maker to brew at 6 a.m., and it greeted me with a fresh pot. That’s automation—simple, efficient, and invisible. It’s about making repetitive tasks faster and error-free, whether in a factory or your kitchen.

Key Differences Between Robotics and Automation

While robotics and automation overlap, they’re distinct in scope, purpose, and execution. Robotics focuses on physical machines with autonomy, while automation optimizes processes, with or without physical components. Let’s break it down:

| Aspect | Robotics | Automation |

|---|---|---|

| Definition | Design and use of physical robots | Streamlining processes with technology |

| Physical Component | Always involves physical machines | Can be physical or software-based |

| Autonomy | High autonomy, often with AI | Minimal to no autonomy, rule-based |

| Examples | Robotic arms, drones, humanoid robots | Conveyor belts, email schedulers, CRMs |

| Complexity | High, integrates multiple disciplines | Varies, can be simple or complex |

| Cost | Often expensive due to hardware | Can be low-cost for software solutions |

Why the Distinction Matters

Confusing robotics with automation is like mixing up a chef with a recipe app. Robotics involves creating intelligent machines that adapt, while automation focuses on efficiency and consistency. Knowing the difference helps businesses choose the right tools, saving time and money.

Robotics: The Brainy Machines

Robotics is where engineering meets creativity. A robot isn’t just a machine; it’s a system with sensors, actuators, and often AI, allowing it to interact with its environment. Think of a self-driving car navigating traffic or a surgical robot assisting in delicate operations.

How Robotics Works

Robots rely on three core components: sensors to perceive the world, processors to make decisions, and actuators to move or act. For example, a warehouse robot uses cameras to “see” shelves, algorithms to plan its route, and wheels to move. This synergy makes robotics ideal for tasks requiring adaptability.

Real-World Applications of Robotics

- Manufacturing: Robotic arms assemble cars with precision.

- Healthcare: Surgical robots perform minimally invasive procedures.

- Agriculture: Drones monitor crops and spray fertilizers.

- Entertainment: Think of animatronic figures at theme parks.

Last year, I visited a factory where robotic arms danced in sync, assembling smartphones. It was mesmerizing, but what struck me was their ability to detect and fix errors on the fly—something a simple automated conveyor couldn’t do.

Automation: The Efficiency Engine

Automation is the backbone of efficiency, reducing human effort in repetitive tasks. It can be as simple as a spreadsheet macro or as complex as a fully automated warehouse system. Unlike robotics, automation doesn’t need physical form—it thrives in code and systems.

How Automation Works

Automation uses predefined rules or algorithms to execute tasks. For instance, a CRM system automatically sends follow-up emails to leads based on triggers. It’s less about thinking and more about doing—consistently and quickly.

Real-World Applications of Automation

- Business: Automated invoicing saves hours of manual work.

- Logistics: Conveyor systems sort packages in warehouses.

- Home: Smart thermostats adjust temperatures based on schedules.

- Marketing: Tools like HubSpot automate email campaigns.

I once automated my social media posts using a scheduling tool. It saved me hours weekly, but when a post needed tweaking for context, I had to step in—automation doesn’t “think” like a robot does.

Pros and Cons of Robotics

Robotics offers incredible potential but comes with trade-offs.

Pros of Robotics

- Adaptability: Robots can learn and adjust to new environments.

- Precision: Ideal for tasks requiring high accuracy, like surgery.

- Safety: Handles dangerous tasks, like bomb disposal.

Cons of Robotics

- High Costs: Building and maintaining robots is expensive.

- Complexity: Requires skilled engineers for design and upkeep.

- Job Displacement: Can reduce demand for manual labor.

Why Robotics Excites (and Scares) Us

Robotics feels like a leap toward the future, but it’s not without hiccups. I recall a friend worrying about robots replacing his factory job. While valid, the fear often overshadows how robotics creates new roles, like robot maintenance technicians.

Pros and Cons of Automation

Automation is a game-changer for efficiency, but it’s not perfect.

Pros of Automation

- Cost-Effective: Software solutions are often cheaper than robots.

- Scalability: Easily applied across industries and tasks.

- Consistency: Eliminates human error in repetitive processes.

Cons of Automation

- Limited Flexibility: Struggles with tasks requiring judgment.

- Dependence: Over-reliance can lead to system failures.

- Upfront Investment: Complex systems require significant setup.

Automation’s Quiet Power

Automation’s strength lies in its simplicity. My brother’s small business uses automated payroll software, cutting his admin time in half. But when tax laws changed, the system needed manual updates—automation excels in stability, not adaptability.

Why the Difference Matters for Businesses

Choosing between robotics and automation depends on your goals. Robotics suits tasks needing flexibility, like a robot barista crafting custom coffee orders. Automation is better for repetitive, predictable tasks, like sorting emails. Misjudge your needs, and you could overspend or underdeliver.

Case Study: Amazon’s Warehouse Revolution

Amazon uses both robotics and automation. Its Kiva robots move shelves to workers, adapting to warehouse layouts. Meanwhile, automated conveyor belts sort packages based on fixed rules. This blend maximizes efficiency, showing how the two technologies complement each other.

Robotics vs. Automation: Which Should You Choose?

The choice hinges on your needs, budget, and industry. Here’s a quick guide:

- Choose Robotics If: You need adaptability, precision, or physical task execution (e.g., manufacturing, healthcare).

- Choose Automation If: You want efficiency, scalability, or cost-effective solutions (e.g., marketing, logistics).

- Combine Both: For complex systems, like warehouses or smart factories, where robotics handles dynamic tasks and automation streamlines processes.

A Personal Lesson in Choice

When I helped a friend automate his e-commerce store, we considered a robotic packing system. The cost was astronomical, so we opted for automated inventory software instead. Sales soared, and he didn’t need a robot to smile at the results.

People Also Ask (PAA) Section

Here are answers to common questions from Google’s “People Also Ask” for “Robotics vs. Automation”:

Is robotics a form of automation?

Robotics is a subset of automation, but not all automation involves robotics. Automation encompasses any technology that reduces human effort, while robotics specifically involves physical machines with autonomy.

What are examples of automation that aren’t robotics?

Examples include email marketing tools, automated billing systems, and smart home devices like thermostats. These rely on software or simple hardware, not complex robots.

Can robotics and automation work together?

Absolutely. Many industries combine them, like Amazon’s warehouses, where robots move goods and automated systems track inventory, creating a seamless workflow.

Why is robotics more expensive than automation?

Robotics involves physical hardware, sensors, and AI, which drive up costs. Automation often relies on software or simpler hardware, making it more affordable.

Tools and Resources for Robotics and Automation

Best Tools for Robotics

- ROS (Robot Operating System): Open-source framework for robot development.

- Arduino: Affordable for prototyping small robots.

- ABB RobotStudio: For simulating industrial robotic systems.

Best Tools for Automation

- Zapier: Connects apps for workflow automation.

- UiPath: Leading RPA (Robotic Process Automation) platform.

- IFTTT: Simplifies home and small business automation.

Where to Learn More

- Robotics: Check out MIT’s OpenCourseWare for free robotics courses.

- Automation: Explore Automation Anywhere University for RPA training.

- Both: Join communities on Reddit’s r/robotics or r/automation.

The Future of Robotics and Automation

The line between robotics and automation is blurring as technology evolves. AI is making automation smarter, while robotics is becoming more accessible. In the next decade, expect robots to handle more human-like tasks and automation to infiltrate every corner of our lives, from self-managing homes to AI-driven supply chains.

A Glimpse Ahead

Imagine a world where your robot chef cooks dinner while your automated home adjusts lighting and music to your mood. I recently saw a prototype robot that could fold laundry—clumsily, but it’s a start. The future is exciting, but it demands we understand these technologies to harness them wisely.

FAQ Section

What’s the main difference between robotics and automation?

Robotics involves physical machines with autonomy, like robotic arms or drones, while automation focuses on streamlining processes, often through software, like email schedulers or conveyor belts.

Can automation exist without robotics?

Yes, automation can be purely software-based, like a CRM system or automated billing, requiring no physical robots.

Is robotics more advanced than automation?

Robotics is often more complex due to its integration of AI, sensors, and hardware, but automation can be equally sophisticated in optimizing processes.

How do businesses benefit from robotics and automation?

Robotics enhances precision and adaptability for complex tasks, while automation boosts efficiency and reduces costs for repetitive processes.

Where can I start learning about robotics and automation?

Start with online platforms like Coursera for robotics courses or Automation Anywhere for automation training. Communities like Reddit’s r/robotics are great for networking.

Conclusion: Why It Matters to You

Understanding the difference between robotics and automation isn’t just academic—it’s practical. Whether you’re a business owner eyeing efficiency, a student exploring career paths, or a curious mind, knowing which technology fits your needs can save time, money, and effort. Robotics brings adaptability and precision; automation delivers speed and consistency. Together, they’re shaping a future where work is smarter, not harder. So, next time you see a robot or an automated system, you’ll know exactly what’s at play—and why it matters.